This post is to release my version of a low cost and small delta printer that I call SlideRap .

This design takes direct inspiration on two printer: 3DR and Kossel Mini, and most of its printed parts are based on the parts of this printers. Many people and projects inspired so thank you all who take the time to share their ideas with the community.

The Printer

Printed Parts - SlideRap prototype uses parts made of PLA and some made of ABS, but it can all be printed with PLA.

All parts where printed in my base printer (the one in the previous post) with 0.2mm layers, and 30% honeycomb infill, with two perimeters.

1x3DR_Jhead_groove_mount_V2_001_PUSHFIT_RTP -By Richard Horne(RichRap)

1 x SlideRap spool holder bottom

1 x SlideRap Spool holder top

2 x SlideRap tube holder

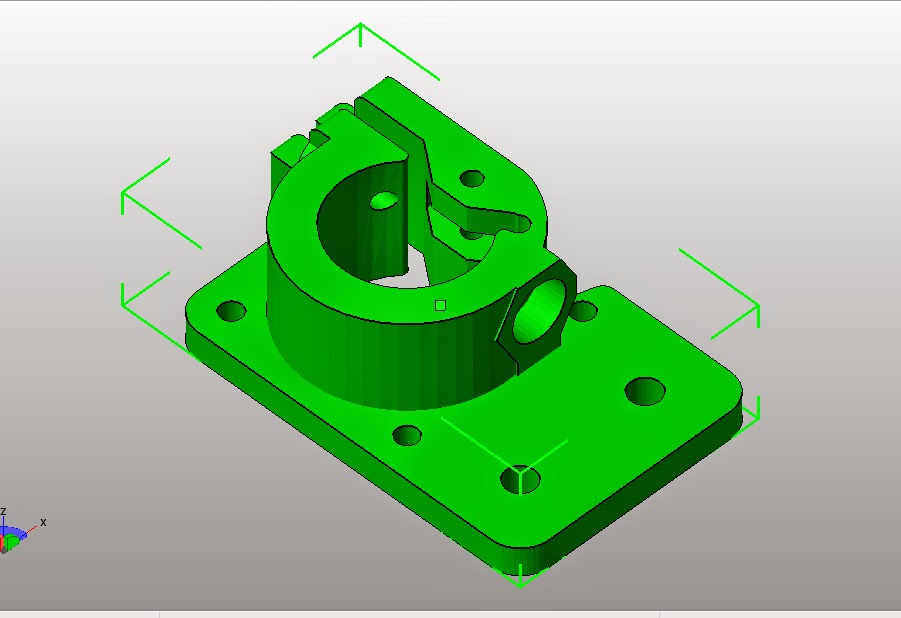

1 x SlideRap extruder

Mechanical / Frame

This printer uses 3 vertical extrusions with 500mm and 6 horizontal extrusions with 200mm each.In this case they are Motedis extrusions.

The diagonal rods or delta arms are made of 3mm carbon rods, and Traxxas joints (12). I glued the rods into the traxxas joints with super-glue.

The bed and the top are pieces of acrylic 5mm thick.

I considered to use spectra line but went with GT2 belts for this time.

Other parts:

T-slot nut - 31

M4x10mm socket head - 31

M3 nuts - aprox 15

M3 washer - aprox 10

M3x10mm socket head - aprox. 50

M3x16mm socket head - aprox 20

M3x20mm socket head - 5

M4x40mm screw - 4

M4 nut - 6

M4 washer- 4

M8x40mm screw - 1

M8 nut - 1

M8 washer -2

606zz bearing - 2

623zz bearing - 7 (two on each idler, one on the extruder)

PTFE tube 2mm inner, 4mm outer

Pneumatic fittings - 2 (i´m using the one available on reprapworld )

MK7 hobbed insert

Spring 5mm diameter

Nema17 stepper motor - 4

endostop - 3

eletronics board - 1 (in this case I reused my old sanguinololu 1.2)

Hotend - 1 - I´m using a J-head 1.75mm

Cable wrap

Zippties

wires, power supply...

Does it work?

Yes it does!

Well, at least the motion system part does work, but my hot-end was badly assembled (by me..) and it "leaks" filament that fall on top of the printed parts..

other then that this was actually my first machine that uses a cold printing bed with blue painters tape and i´m finding really hard to remove the prints from the base (maybe I´m printing to close to the printbed) and this one tear the base of the vase..

But apart from the fact that the J-head that I assembled, and that I need to raise the print head I am happy with the resulting printed part (using Faberdashery filament)

So what's next for this printer?

Well first I have to fix my hot-end or try to make a complete DIY hot-end just to try one out. In my other set up I have a E3D v5 and I really like it, so if i have to get a new hot-end I might go with that.

Second I have to let this carriages do a couple of hours running to see if I need to improve any part of their design. This ones were printed with Faberdashery PLA and they are working fine, but they will be replaced with some printed with IGUS Tribo-filament. I have a small sample to try soon.

The plastic parts can be found at YouMagine

I hope to see this carriage on some cartesian prints, lets see if that happens..

And for last here is the video of the first real print.

Cheers, and keep making stuff!

Hi, nice work! Are you happy with the sliding solution? Don't the sliders wear out too often?

ReplyDelete